Red Bull Ring Formula1 Trophy: Where Emotion Meets Excellence

The Magic of the Red Bull Ring Formula1 Trophy – A Fusion of Design, Emotion & Quality by Bernd Kussmaul GmbH, Making Motorsport History.

Whether it’s a prototype, a one-off or a small series – with quality awareness and passion, we develop and manage handmade one-offs or complex series productions with our unique network of production specialists. A partnership and long-term customer relationship is important to us — we will do everything we can to maintain these values in confidence and are always open to communicative exchange.

We accompany your product idea from design to realisation. Our greatest innovative strength lies in the optimisation and reinterpretation of standard solutions.

We create technical excellence with precision and dynamism. We are an internationally active technology company with 40 employees.

We have specialised in individual manufacturing solutions for niche products, small series and prototypes with high technical demands.

We put the needs of our customers at the centre of our daily work and always convince through our unique designs and outstanding quality, as well as through values such as delivery reliability and dependability.

The PG-Bugatti-bike stands out as a lightweight in its class. Purist design speaks for the brand. The new development from Bugatti has been agilely driven ahead by muscle power. The stylish urban bike captivates through its simplicity and perfect form. A high-‘ leight ‘, which gets the appropriate individuality in the KUSSMAUL manufactory.

Rolls-Royce “Ennobles” Kussmaul: As a series supplier for the Phantom 8, the company manufactures the Zierteil, consisting of a high-gloss polished aluminium beam as well as two filigreely lasered and Feinstgebürsteten stainless steel sheets for the dashboard “the Gallery”. Also included in the delivery is the casing for the clock; which is guilloche and silver-plated in the premium version.

In the lattice roller developed for the production of contact lenses, Kussmaul combined technology and elegance in a 14-step manufacturing process to produce a highly-precise masterpiece. With a 0.02 mm precision in terms of form and position over a length of 630 mm, the fulfilment requirements of the narrow tolerance range for the rejection rate of contact lens production was reduced by 23 percent.

Take a seat in our reading corner and learn more about us.

The Magic of the Red Bull Ring Formula1 Trophy – A Fusion of Design, Emotion & Quality by Bernd Kussmaul GmbH, Making Motorsport History.

A Singer Driving Experience – thanks to our guests From April 10th to 12th, 2025, we had the privilege of experiencing something truly special in our venue. Thanks to the visit of numerous guests, it was not just an event, but rather a genuine experience filled with encounters, emotions, and shared excitement. It was a…

Sport is more than competition. It’s about the shared journey, the sense of togetherness, and the trust within a team – all of which are symbolized by the new trophy of the STB Mixed Cup 2025, designed by Bernd Kussmaul GmbH. Each athlete takes home a piece of the trophy as a medal – a…

“GRAVITY OF LIGHT” – Poggenpohl’s icon +MODO as a study by Kussmaul GmbH at the Salon del Mobile 2024 Photocredit: Steffen Jahn INNOVATIVE INTERPRETATION OF THE PENSI DESIGN +MODO Innovation has a tradition at Poggenpohl. In January 2023, the Herford luxury kitchen company sought contact with the Weinstadt-based manufacturer Kussmaul for the…

Als Einzelkämpfer im Rennsport begann die Karriere von Bernd Kußmaul, heute führt der 60-Jährige ein Unternehmen mit 60 Mitarbeitenden in Weinstadt in Baden-Württemberg. Was dort gefertigt wird, lässt sich irgendwie schwer erklären, das muss man gesehen haben. Diese Einladung haben nun Grünen-Landtagsabgeordnete Petra Häffner und rund 20 ihrer Gäste angenommen. Photocredit: Bernd Kussmaul GmbH …

Bernd Kussmaul produces Red Dot: Best of the Best Trophy With the illuminated medals for the 2019 Artistic Gymnastics World Championships in Stuttgart, Bernd Kussmaul created a true world-first innovation. This caught the attention of the international design scene — and led to contact with the organizers of the Red Dot Design Award, the most…

We have often heard that internationalization places new demands on the market. But what does that actually mean in detail for a medium-sized family business from Baden-Württemberg, for example? The answer: It has to act. Bernd Kußmaul GmbH can boast another milestone in its success story. Around 60 employees from Weinstadt and the surrounding area…

Dass die Internationalisierung neue Anforderungen an den Markt stellt, haben wir schon oft gehört. Was heißt das aber eigentlich im Detail beispielsweise für ein mittelständisches Familienunternehmen aus Baden-Württemberg? Die Antwort: Es muss agieren. Die Bernd Kussmaul GmbH kann einen weiteren Meilenstein in ihrer Erfolgsgeschichte vorweisen. Rund 70 Mitarbeitende aus Weinstadt und Umgebung sorgen dafür, dass…

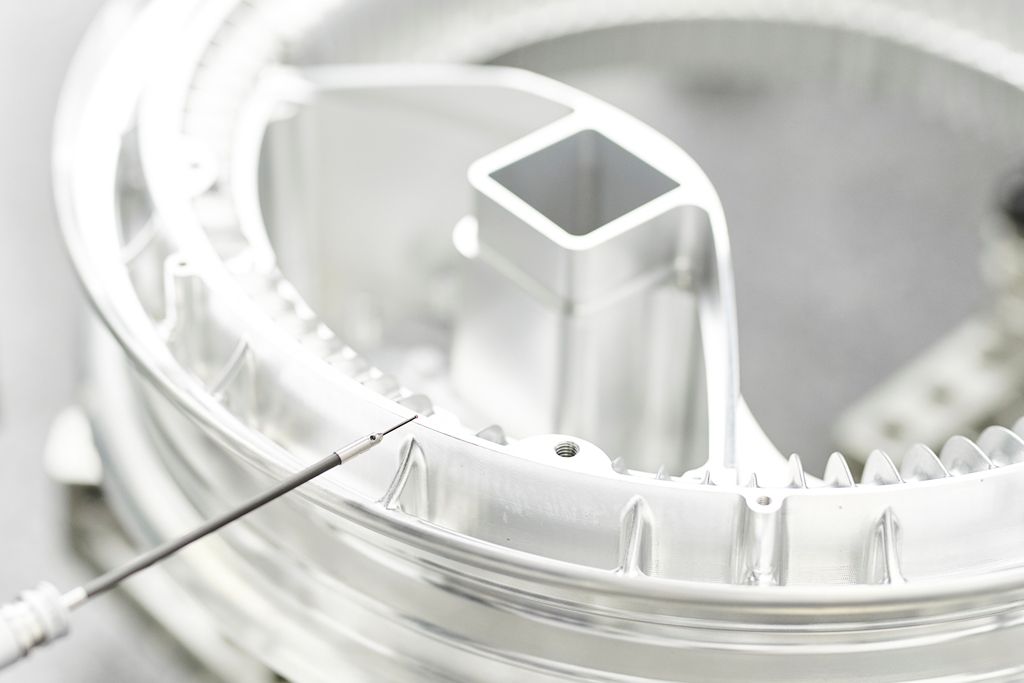

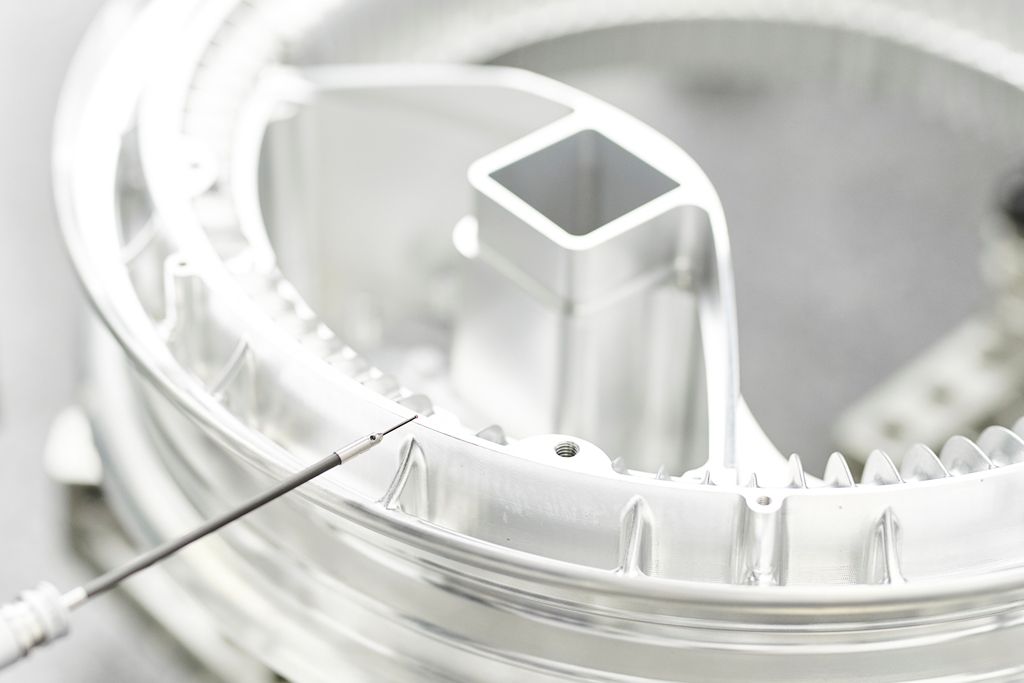

Photocredit: Singer They are automotive diamonds. We are talking about rims that have never been seen before and give the Porsche 911 reimagined by Singer – DLS Turbo the final touch of unique aesthetics. Created in the Californian think tank Singer Vehicle Design together with its trusted partner BBS and brought to life in Weinstadt,…

It must come from the heart, what should work on hearts.

Johann Wolfgang von Goethe (German poet and naturalist, 1749-1832)

FINALLY!

After a break of almost three years, Bernd Kußmaul GmbH once again invited visitors to its premises

70,000 “Christmas surprise” for the staff of Rems-Murr-Kliniken

Take: a sliced bagel roll, five slices of avocado, five slices of tomato, five onion rings, 10 rocket leaves, twelve kilograms of gold – and two Swabian rascals who compose an extraordinary and unique work of art from it.

The Weinstädter Manufaktur was allowed to actively participate in the design and creation of the first prototype vehicle of eTree-mobility and support this innovative project.